The Features of Sintered Mesh Filter Compared with Traditional Filter

What does "Sintered" mean?

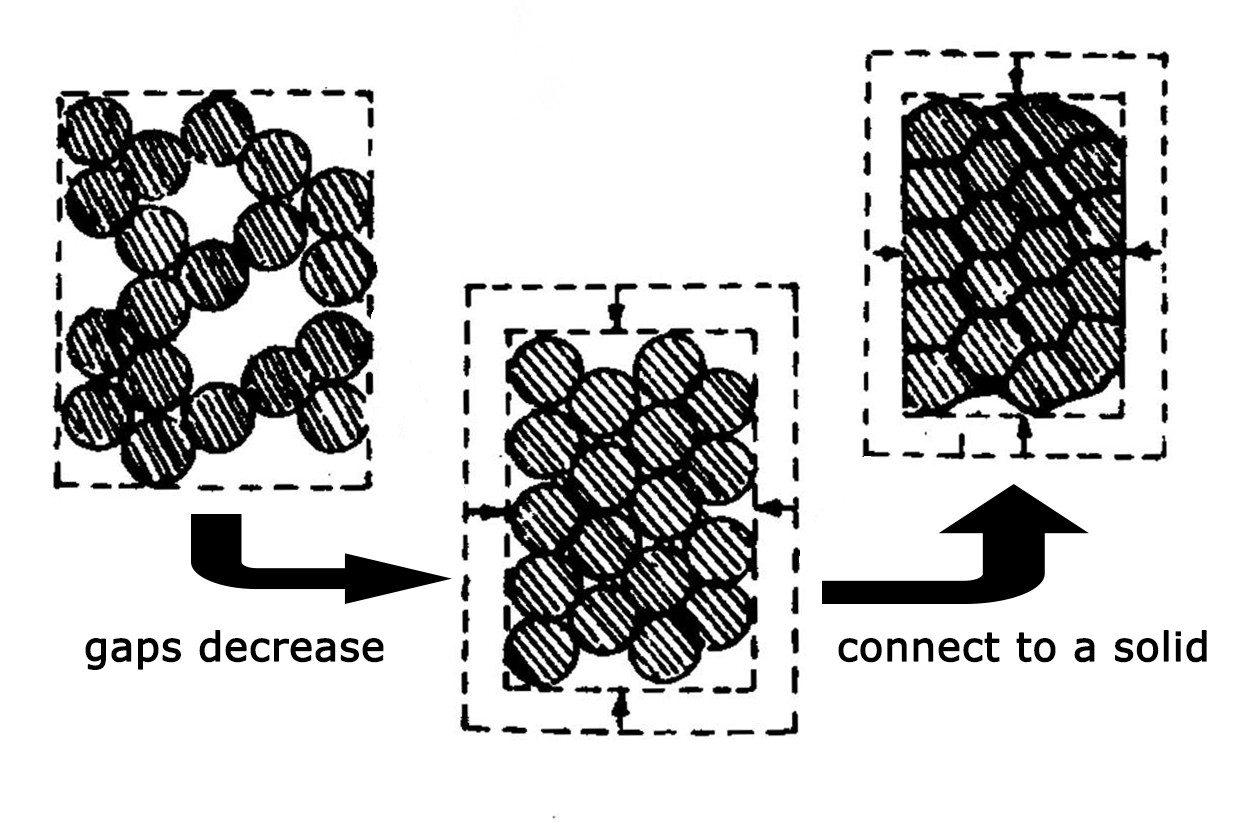

"Sintered" is a traditional processing technology that refers to heating the powdered materials at a high temperature below their melting point, and forming a dense and polycrystalline sintered body through physical and chemical reactions.

What is "Sintered Mesh"?

"Sintered Mesh" is made of five to seven layers of woven wire mesh, through a lamination and vacuum sintering into a unit. The material of sintered mesh is usually stainless steel 304/316/316L. The filter accuracy can be customized at a range of 1 ~ 300μm, and is uniform and stable, the mesh hole is not easy to deform during the filter's working.

Sintered metal mesh has a great performance in high temperature resistance and high corrosion resistance, it can work in a temperature range from -200 to 650℃, and PH 0-14. Sintered mesh can also be washed and reused, it is easy to clean and has a long service life to save the whole cost.

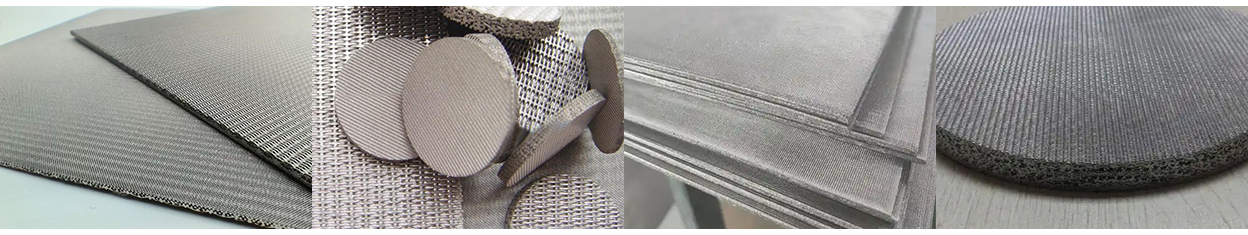

Sintered mesh has a high mechanical strength and high pressure resistance, and it is also easy to mold, process, and weld. It can be processed into various forms of sintered filter elements, such as circular, cylindrical, conical, and corrugated shapes.

Mostly, a whole sintered mesh has five types of layers, including protective layer (80~100μm), separation layer (40~60μm), filter layer (2~20μm), supporting layer (200~300μm), and skeleton layer (thickness 1~2mm). It has been widely used in machinery, chemical fibers, petrochemicals and pharmaceutical industry according to its excellent filter performance.

.png)

Production Steps of Sintered Mesh

Structure Design, Arrangement, and Stacking

According to the filtration requirement, create a reasonable design in precision, thickness, layers, and wire mesh structure of the sintered mesh. Then, the single-layer metal wire mesh is stacked according to the process requirement, and the four corners are spot-welded together to form a sintered mesh assembly.Pressure and Vacuum Sintering

Put the whole sintered mesh into the furnace, and pump out the air in the furnace to maintain a vacuum state inside the furnace. Then increase the temperature inside the furnace to 295-305℃, and inject hydrogen gas to keep the pressure inside the sintering furnace at 39–41 Pa. Start the hydraulic mechanism at the same time to increase the pressure at 0.5-1.5kg/cm² on the sintered mesh, and then continue heating to 1200℃–1300℃ for firing.Cool Down and Take Out

Turn off the heating device and hydraulic mechanism, and rapidly cool the temperature to 1080℃–1120℃ through cooling gas. And then close the hydrogen inlet valve, making the temperature quickly drop to 280℃–310℃ within 15 minutes, afterward cooling naturally to 35℃–45℃. In the end, remove the sintered mesh from the sintering furnace.Final Production processing

According to the usage requirement, doing surface treatment, cutting, polishing and other steps to the sintered mesh.Henan Top Environmental Protection Equipment is a physical factory with 26000 square meters. We have advanced sintering furnace, laser cutting machine, CNC machine tool and other production equipment, and we have strict production process to ensure the product quality.

The Features of Sintered Mesh Filter Compared with Traditional Filter

Material and Production Technology

►The sintered mesh filter element is made of metal wire mesh, like stainless steel 304/316/316L and other alloys.►The traditional filter elements for oil or air usually use fiberglass, paper, polyester, PP, and some other composite parts.

Adaptability of Working Environment

►The sintered metal mesh filter is produced through high-temperature sintering technology, and all the connections of the filter cartridge are made using metal welding technology. It has a great mechanical strength and a good performance in high-temperature and high-corrosion working environments.►The ordinary filter cartridge, like hydraulic oil filter, mostly has a simple structure. And usually use adhesive to connect the end cover. They can only work under normal temperature and pressure working conditions.

Filtration Performance

►Sintering filter cartridge has a high filtration accuracy up to 1μm, it can effectively remove fine particles and suspended solids. Sintered mesh filter has a uniform structure, low resistance to fluid flow, high throughput, and minimal pressure drop variation, so the filtration efficiency is very stable.►Traditional filters have lower filter accuracy and are typically used for pre-filtration or coarse filtration. The pressure difference often increases rapidly, making them prone to blockages.

Service Life

►Sintered mesh filter can be washed easily, so it can be reused many times. Even though sintered filter cartridges have a higher price compared with normal filter elements, they have a long service life and can save the whole cost.►Traditional filter elements are mostly disposable or have a short lifetime, and need to be replaced frequently. Have high maintenance costs.

Sintered Mesh Filter Pictures

How to maintain sintered mesh filter elements in daily use?

♦ Regular Inspection

During the production process, the filter element's condition should be checked regularly, observing parameters such as the pressure difference between the inlet and outlet and the filtration flow rate. When the pressure difference increases significantly or the flow rate decreases significantly, it indicates that the filter element is clogged and needs to be cleaned through the correct methods or replaced promptly. Prolonged operation under excessive pressure can cause permanent blockage. At the same time, avoid operating at excessive temperatures or pressures. The operating temperature and pressure must be within the design range; sudden increases in temperature and pressure are most damaging to the filter element.♦ Correct installation and removal

When installing and removing the five-layer sintered mesh filter element, strictly follow the operating procedures to avoid damaging the filter element due to improper operation. Do not use steel brushes or knives, and do not tap or strike the outer wall of the filter element, as this will directly damage the sintered microporous structure. During installation, ensure the filter element is properly seated and sealed to prevent fluid leakage through the gap between the filter element and the mounting base. When removing the filter element, proceed with caution to avoid bumping or pulling on it, which could cause deformation or damage.♦ Proper storage

After cleaning, the filter element should be thoroughly dried and stored in a dry, clean environment to prevent dust, oil, and other impurities from contaminating it again. Alternatively, the filter element can be placed in a dedicated storage box or bag and stored in a well-ventilated warehouse to protect it from moisture and corrosion.Manufacturer&Supplier

Henan Top Environmental Protection Equipment is a manufacturing company based in Henan, China, producing a full range of filter cartridges and filter housings. Our factory is equipped with modern rolling, slitting, and welding machinery, along with multiple automated production lines that help us deliver stable quality and large-volume output.

Our engineering team is made up of experienced professionals who provide practical technical support, while our sales and after-sales staff ensure smooth communication and reliable service. Each product is manufactured under strict quality management to meet demanding performance requirements.

We also focus heavily on customized filtration solutions. Depending on the application, we can choose the right materials and design custom sizes, colors, packaging, labels, and logos. With strong in-house production capability, many new items can be developed and completed within a week.

The company holds CE and ISO certifications and has obtained several R&D patents. With more than 15 years of export experience, our products are supplied to customers in over 100 countries and regions, including North America, Eastern Europe, the Middle East, and Southeast Asia. Guided by responsibility, professionalism, and integrity, we aim to provide durable products and dependable service that earn long-term trust from our global customers.

- How to Choose a Suitable Hydraulic Oil Filter

- Types of Hydraulic Oil Filter Element

- Filtration Material of Hydraulic Oil Filter

- The function of the inner and outer skeletons of the hydraulic oil filter element

- Which is better, Spiral Skeleton or Punch Plate Skeleton

- The difference between Carbon Steel and Stainless Steel

- The Difference Between Sintered Filter and Ordinary Filter

- How to choose the filtration material of dust collection air filter