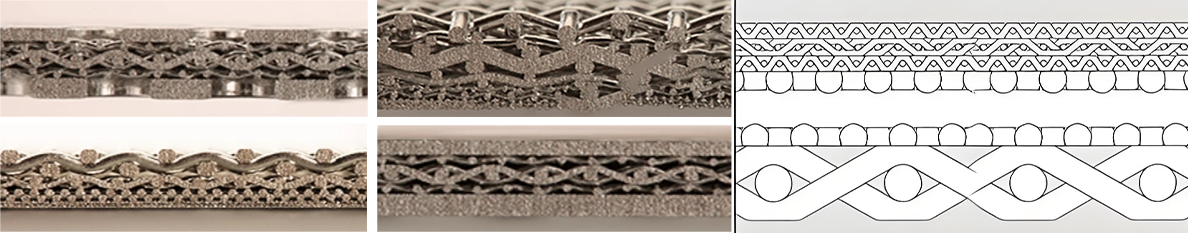

The Stainless Steel Sintered Mesh Filter is made of five layers of woven stainless steel mesh that are vacuum-sintered into a single unit. The multi-layer structure is composed by a protective layer, a precision control layer, a diffusion layer, and reinforced support layers, and it has a stable and uniform pore design ideal for demanding industrial filtration.

Sintering filter element is usually manufactured with SUS304/316/316L stainless steel. This sintered mesh filter element delivers reliable performance across a wide temperature range from –200°C to 650°C, with filtration ratings available from 1 to 300 microns. It offers outstanding mechanical strength, excellent pressure resistance, consistent porosity, and good permeability. The material is wear-resistant, corrosion-resistant, and easy to clean, making it suitable for repeated use.

The stainless steel sintered mesh filter cartridges are widely used in hydraulic and lubrication systems, chemical fiber melt filtration, pharmaceutical material processing, and filtration of corrosive fluids in petrochemical applications, and other critical industrial processes. It has a long service life and a high-precision solution for applications requiring dependable multi-layer sintered wire mesh filters.

| Product Name | Stainless Steel Sintered Mesh Filter / Sintered Metal Mesh Filter |

| Material | Stainless Steel 304/316/316L |

| Filter Precision | 1 -- 300μm |

| Working Temperature | -200 -- 650℃ |

| Porosity | 35% -- 50% |

| Pressure Resistance | Up to 30 MPa |

| Corrosion Resistance | PH 0-14 |

| Working Media | Air / Water / Oil / Viscous Liquid / Chemical Liquid |

| Connection | Standard Thread / Flange / Quick Connection / Tie Rod Connection / Custom |

.png)

High thickness metal plate, espacially suitable for the high pressure working condition. Withstand the system pressure shocks, to prevent interlayer misalignment and

ensure the sinter filter' shape stability, serve as a whole supporting function in the sintered mesh filter cartridge.

Henan Top Environmental Protection Equipment is a manufacturing company located in Henan, China, focusing on a wide range of filter cartridges and filter housings. Our facility is equipped with advanced production equipment, including rolling, slitting, and welding machines, as well as several automated lines that allow us to deliver consistent, high-quality products in large volumes.

Our R&D team consists of experienced engineers who provide solid technical support, complemented by a knowledgeable sales and after-sales staff dedicated to reliable service. Every product is produced under strict quality control procedures to ensure it meets demanding performance standards.

We specialize in customized filtration solutions. According to customer needs, we can select suitable raw materials for various working conditions and offer custom dimensions, colors, packaging, labels, logos, and graphics. With strong manufacturing capability, we are often able to complete new product development and production within a week.

The company has earned CE and ISO certifications and holds several R&D patents. With more than 15 years of export experience, our products are shipped to over 100 countries and regions, including North America, Eastern Europe, the Middle East, and Southeast Asia. Guided by principles of responsibility, professionalism, and integrity, we have built long-term trust and recognition throughout the industry by consistently delivering dependable products and service.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)