How to Choose a Suitable Hydraulic Oil Filter

Dec 18, 2025

The hydraulic oil filter element is an important component in a hydraulic filtration system, ensuring the hydraulic system operates stably.

Choosing the right hydraulic oil filter cartridge is a crucial yet frequently mishandled task. Selecting the correct filter ensures hydraulic system stability and extends equipment lifespan; choosing the wrong one not only fails to provide proper filtration but can also lead to pressure differential alarms and premature oil pump failure.

Several factors need to be considered when selecting a hydraulic filter cartridge, including filter type, filter media, flow rate, working pressure, working temperature, viscosity, and so on. Now I'll introduce how to select a hydraulic oil filter that is suitable for your machine and hydraulic system.

There are three main types of hydraulic oil filter elements, including suction oil filter, pressurized oil filter, and return oil filter. They have different functions and install locations, so you need to confirm which types of filter you need in advance.

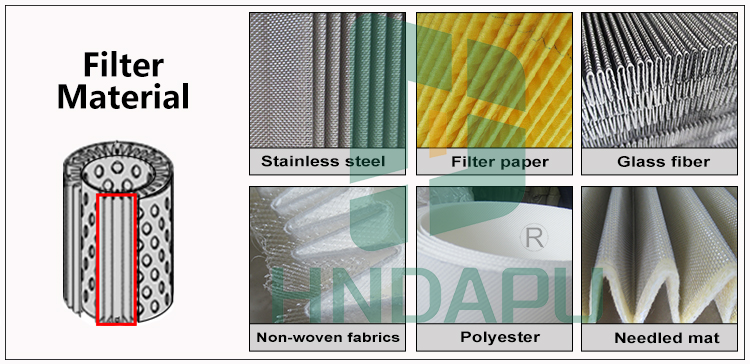

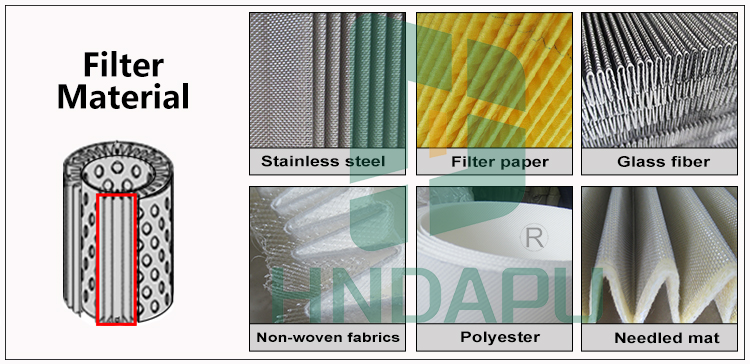

Filter material is the most important part of a hydraulic filter element. Different filter media have different filter performance under the same filter accuracy, so how to choose the correct filter media that matches the actual working condition is difficult and important. Here are some suggestions for choosing a filter material that is suitable for your machine and hydraulic system. TOPEP as a filter manufacturer with years of experience, has a professional technical team to provide you with the most suitable design of filter cartridges.

a. Glass Fiber

Glass fiber filter media is a fiber filter media made from molten glass. It has a multi-layered random fiber structure, in which particles are "captured" inside the fibers rather than clogging the surface, thus belonging to deep filtration.

► Press oil filter/Return oil filter --- 90% use fiberglass

► Features

High filter accuracy, intercepts the particles in the 3–10 μm range effectively;

Smooth surface, low filtration resistance;

Large dirt holding capacity.

► Attention

The material is brittle, can't resistant strong impacts;

Do not have a great tolerance for moisture (but better than filter paper).

b. Filter Paper

Filtration paper usually does surface and shallow filtration, suitable for a normal return oil filter, the machine does not work continuously, and a program that does not have much budget.

► Mostly used for engine oil filter

► Features

Low price;

Good filter performance in intercepting the large particles.

► Attention

Easy to get clogged, short service life;

Low filter accuracy, can't intercept fine particles;

Easy to deform in a high-temperature and high-humidity working environment.

c. Stainless Steel Mesh

The stainless steel filter mesh belongs to surface filtration, which intercepts the particles outside the filter net.

► Mostly used for suction oil filter, or pressurized oil filter in high-temperature, high-viscosity oil, and high-impact working conditions.

► Features

High mechanical strength, not easy to deform;

Can be cleaned and reused, has a longer lifespan.

► Attention

Low filter accuracy, can not filter the fine particles effectively.

d. Metal Sintered Mesh/Powder Sintered Material

The sintered mesh filter and porous powder sintered filter are designed for extremely harsh working conditions.

► Features

High-temperature(>200℃,up to 650℃), and high-corrosion resistance;

The structure is extremely stable, could withstand high pressure and impact;

Can be cleaned easily.

► Attention

The price is higher than other materials.

Besides the different filter accuracy of different types of hydraulic filter elements, the precision of the filter media is also affected by the viscosity and flow rate of the filtered oil.

We usually want to pursue more effective filter performance, but higher filtration precision is not always better. If the oil that needs to filter has high viscosity, using a high precision filter media will cause serious blockage; and if the Liquid flow rate is large, excessive precision can easily lead to greater resistance, which affects the filtration performance and lifespan of the hydraulic filter element.

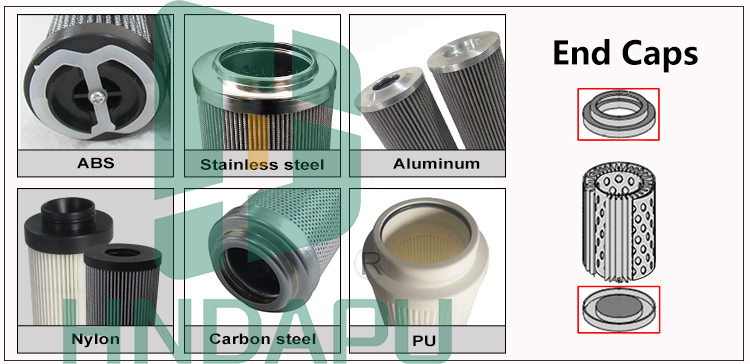

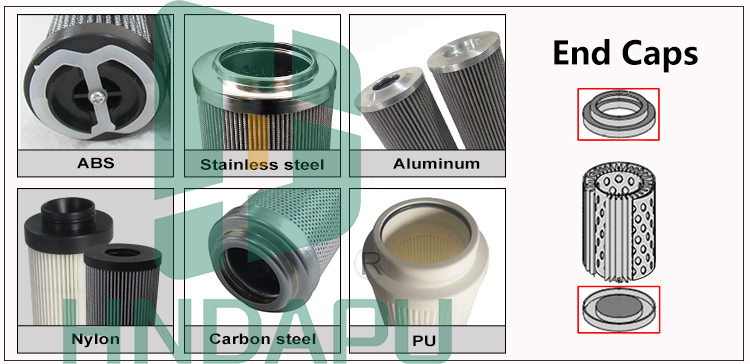

The hydraulic oil filter element will suffer a lot of damage during its operation. The end cover and frame, as the protective parts of a filter cartridge, are also very important components; they often determine whether a filter element can work stably for a long time, and even whether it will "collapse, leak oil, or shed powder". End caps and skeletons can be made of different materials; choosing the right material for them is helpful to extend the filter element's lifespan and protect the hydraulic system.

End caps in the oil filters typically serve to seal, support, and secure the filter media.

2. How to select the filter frame

.png)

Choosing the right hydraulic oil filter cartridge is a crucial yet frequently mishandled task. Selecting the correct filter ensures hydraulic system stability and extends equipment lifespan; choosing the wrong one not only fails to provide proper filtration but can also lead to pressure differential alarms and premature oil pump failure.

Several factors need to be considered when selecting a hydraulic filter cartridge, including filter type, filter media, flow rate, working pressure, working temperature, viscosity, and so on. Now I'll introduce how to select a hydraulic oil filter that is suitable for your machine and hydraulic system.

Verified the Filter Type You Need

There are three main types of hydraulic oil filter elements, including suction oil filter, pressurized oil filter, and return oil filter. They have different functions and install locations, so you need to confirm which types of filter you need in advance.

| Suction Oil Filter | Press Oil Filter | Return Oil Filter | |

| Location | in the oil tank suction port of the oil pump |

oil pump outlet on the high-pressure lube line |

after the hydraulic components on the return lube |

| Filter Accuracy | 10~250μm | 2~10μm | 10~25μm |

| Main Function | intercept the large particulate impurities to protect the oil pump | filter the high-pressure oil output from the oil pump, protect the spool valves and servo valves | filter the particles due to the machine operation, prevent them from flowing back to the oil tank |

How to Select a Filter Media?

Filter material is the most important part of a hydraulic filter element. Different filter media have different filter performance under the same filter accuracy, so how to choose the correct filter media that matches the actual working condition is difficult and important. Here are some suggestions for choosing a filter material that is suitable for your machine and hydraulic system. TOPEP as a filter manufacturer with years of experience, has a professional technical team to provide you with the most suitable design of filter cartridges.

1. Introduction of different filter media

a. Glass Fiber

Glass fiber filter media is a fiber filter media made from molten glass. It has a multi-layered random fiber structure, in which particles are "captured" inside the fibers rather than clogging the surface, thus belonging to deep filtration.

► Press oil filter/Return oil filter --- 90% use fiberglass

► Features

High filter accuracy, intercepts the particles in the 3–10 μm range effectively;

Smooth surface, low filtration resistance;

Large dirt holding capacity.

► Attention

The material is brittle, can't resistant strong impacts;

Do not have a great tolerance for moisture (but better than filter paper).

b. Filter Paper

Filtration paper usually does surface and shallow filtration, suitable for a normal return oil filter, the machine does not work continuously, and a program that does not have much budget.

► Mostly used for engine oil filter

► Features

Low price;

Good filter performance in intercepting the large particles.

► Attention

Easy to get clogged, short service life;

Low filter accuracy, can't intercept fine particles;

Easy to deform in a high-temperature and high-humidity working environment.

c. Stainless Steel Mesh

The stainless steel filter mesh belongs to surface filtration, which intercepts the particles outside the filter net.

► Mostly used for suction oil filter, or pressurized oil filter in high-temperature, high-viscosity oil, and high-impact working conditions.

► Features

High mechanical strength, not easy to deform;

Can be cleaned and reused, has a longer lifespan.

► Attention

Low filter accuracy, can not filter the fine particles effectively.

d. Metal Sintered Mesh/Powder Sintered Material

The sintered mesh filter and porous powder sintered filter are designed for extremely harsh working conditions.

► Features

High-temperature(>200℃,up to 650℃), and high-corrosion resistance;

The structure is extremely stable, could withstand high pressure and impact;

Can be cleaned easily.

► Attention

The price is higher than other materials.

2. Determine the filter material based on the "type of pollutant."

| Type of Pollutant | Recommended Filter Media | Reason |

| Rubber Debris | Glass Fiber | Prevents secondary breakage |

| Metal Filings | Glass Fiber | Strong deep intercept capability |

| Glue/Paint Film | Glass Fiber | Paper filters are easily clogged |

| Welding Slag | Stainless Steel Mesh | High strength, resistant to impact |

| Water-containing Oil | Glass Fiber/Component Material | Paper is most vulnerable to water |

3. Judging the filter media based on temperature and pressure

| <80℃ | Most of the filter material is fine |

| 80–120℃ | Do not suggest using filter paper only |

| >120℃ | Fiberglass, stainless steel mesh, sintered mesh |

| High-voltage pulse system | Fiberglass + Metal support skeleton |

| Frequent start-stop | Avoid paper filter material |

4. Judging the filter material based on working conditions

| Conditions | Preferred filter material |

| Suction oil port | Stainless steel metal mesh |

| Pressure oil | Fiberglass |

| Return oil | Fiberglass or composite material |

| Servo system | High β fiberglass |

| High-temperature oil | Metal mesh / Metal sintered mesh |

| Low budget | Paper / Composite material |

5. Reasonable selection of filter media accuracy

Besides the different filter accuracy of different types of hydraulic filter elements, the precision of the filter media is also affected by the viscosity and flow rate of the filtered oil.

We usually want to pursue more effective filter performance, but higher filtration precision is not always better. If the oil that needs to filter has high viscosity, using a high precision filter media will cause serious blockage; and if the Liquid flow rate is large, excessive precision can easily lead to greater resistance, which affects the filtration performance and lifespan of the hydraulic filter element.

Different Materials of End Caps and Skeleton

The hydraulic oil filter element will suffer a lot of damage during its operation. The end cover and frame, as the protective parts of a filter cartridge, are also very important components; they often determine whether a filter element can work stably for a long time, and even whether it will "collapse, leak oil, or shed powder". End caps and skeletons can be made of different materials; choosing the right material for them is helpful to extend the filter element's lifespan and protect the hydraulic system.

1. How to select the material of filter end caps?

End caps in the oil filters typically serve to seal, support, and secure the filter media.

► Carbon Steel End Cover

Suitable for 70% of the hydraulic oil system. It has a high strength and is not easy to deform, and also has a reasonable cost, can be used in medium-pressure and high-pressure systems. Carbon steel is widely used in hydraulic filters. But it is not suitable for high humidity or corrosive environments, so we must do rust prevention treatment, such as galvanizing, powder coating, and electrophoresis.

► Stainless Steel End Cover

Stainless steel end caps are usually made of stainless steel 304/316/316L, which have better performance for high-temperature resistance and corrosion resistance compared with carbon steel. Therefore, it is more suitable for working environments with poor conditions. Generally, using stainless steel end cover in a hydraulic filter is better than carbon steel, but should notice that stainless steel always has a higher price.

►Nylon/PU End Cover

Nylon, PU, and plastic end caps always have low weight and low price, they can't withstand terrible working conditions, are very easy to deform in high-temperature and high-pressure environments. So these materials are not a better choice for oil filter cartridges, but sometimes can be used in low-pressure system and return oil filter.

Suitable for 70% of the hydraulic oil system. It has a high strength and is not easy to deform, and also has a reasonable cost, can be used in medium-pressure and high-pressure systems. Carbon steel is widely used in hydraulic filters. But it is not suitable for high humidity or corrosive environments, so we must do rust prevention treatment, such as galvanizing, powder coating, and electrophoresis.

► Stainless Steel End Cover

Stainless steel end caps are usually made of stainless steel 304/316/316L, which have better performance for high-temperature resistance and corrosion resistance compared with carbon steel. Therefore, it is more suitable for working environments with poor conditions. Generally, using stainless steel end cover in a hydraulic filter is better than carbon steel, but should notice that stainless steel always has a higher price.

►Nylon/PU End Cover

Nylon, PU, and plastic end caps always have low weight and low price, they can't withstand terrible working conditions, are very easy to deform in high-temperature and high-pressure environments. So these materials are not a better choice for oil filter cartridges, but sometimes can be used in low-pressure system and return oil filter.

2. How to select the filter frame

The function of the filter skeleton is to withstand the system pressure, support and protect the filter media, ensuring the filter media does not deform. The skeleton can be divided into inner skeleton and outer skeleton in terms of function, and can be divided into helical skeleton and punch plate skeleton in terms of structure.

.png)

► Carbon Steel Punch Plate Skeleton

The carbon steel punch frame is the most popular type of filter skeleton. It has a stable structure and good resistance performance of pressure and impact. The aperture and porosity can be customized according to the flow rate, so that carbon steel skeletons are widely used in oil filter cartridges. But carbon steel material must undergo rust prevention treatment same as the carbon steel end cover, and needs to be considered again when oil has a high water content.

► Stainless Steel Punch Plate Skeleton

The stainless steel frame has a great mechanical strength, and can maintain the structure stable under high-pressure and impact conditions. It can also work normally in high-temperature and corrosion environments, which is beneficial to extend the filter element's lifespan. But you need to have more budget if selecting stainless steel as the skeleton material.

► PP/Plastic Skeleton

They are the most problematic structures when the machine is operating. PP and plastic will soften when exposed to high temperatures, and are easy to deform when the machine is operating continuously, they can not withstand the pulse and impact. Usually, they can only be used in low pressure return oil system.

The carbon steel punch frame is the most popular type of filter skeleton. It has a stable structure and good resistance performance of pressure and impact. The aperture and porosity can be customized according to the flow rate, so that carbon steel skeletons are widely used in oil filter cartridges. But carbon steel material must undergo rust prevention treatment same as the carbon steel end cover, and needs to be considered again when oil has a high water content.

► Stainless Steel Punch Plate Skeleton

The stainless steel frame has a great mechanical strength, and can maintain the structure stable under high-pressure and impact conditions. It can also work normally in high-temperature and corrosion environments, which is beneficial to extend the filter element's lifespan. But you need to have more budget if selecting stainless steel as the skeleton material.

► PP/Plastic Skeleton

They are the most problematic structures when the machine is operating. PP and plastic will soften when exposed to high temperatures, and are easy to deform when the machine is operating continuously, they can not withstand the pulse and impact. Usually, they can only be used in low pressure return oil system.

Previous :

Next :

related

- The Features of Sintered Mesh Filter Compared with Traditional Filter

- Types of Hydraulic Oil Filter Element

- Filtration Material of Hydraulic Oil Filter

- The function of the inner and outer skeletons of the hydraulic oil filter element

- Which is better, Spiral Skeleton or Punch Plate Skeleton

- The difference between Carbon Steel and Stainless Steel

- The Difference Between Sintered Filter and Ordinary Filter

- How to choose the filtration material of dust collection air filter