.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

The PARKER 931886 Replacement Hydraulic Oil Filter is designed for high-pressure hydraulic oil filtration systems and serves as a reliable replacement filter element for Parker original models. This hydraulic oil filter element is used in pressure line applications to effectively remove solid particles and contaminants from hydraulic oil, helping to protect pumps, valves, and other critical hydraulic components.

Manufactured with high-quality filter media and precision production processes, the PARKER 931886 replacement hydraulic oil filter offers excellent dirt-holding capacity, stable flow performance, and consistent filtration efficiency under high operating pressure. It ensures reliable hydraulic oil filtration performance even in demanding industrial environments and harsh working conditions.

This hydraulic oil filter element can be customized according to specific system requirements, including size, filtration accuracy, pressure rating, and filter media. As a pressure line hydraulic filter element, it is widely used in industrial machinery, hydraulic power units, and heavy-duty equipment where stable oil cleanliness and system protection are required.

TOPEP is a professional manufacturer of hydraulic oil filter elements, specializing in Parker replacement hydraulic filters and customized filtration solutions. With strict quality control and standardized production processes, TOPEP hydraulic oil filters provide dependable filtration efficiency, long service life, and effective system protection, ensuring hydraulic systems operate smoothly and reliably.

| Part Number | 931886 | Product Type | Hydraulic System Oil Filter |

|---|---|---|---|

| Filter Style | High-Pressure Line Oil Filter | Micron Rating | 74μm |

| Filter Media | Stainless Steel Mesh | Sealing Material | Nitrile |

| Diameter | 38mm | Length | 129mm |

| Working Pressure | (MAX) 21Mpa | Working Temperature | -30℃~110℃ |

| Skeleton | Carbon Steel | End Caps | Carbon Steel |

We can produce various brands of Filters, as long as you have the part number or parameters of filter, we can do it. Just contact us and share your requirement !!!

| 936704Q | 8833-11 | G04276 | 931881 | 901328 | 901661 | 901747 | 907088 | 907230 | 909293 |

| 941584 | R937852Q | R937878Q | 936710Q | 920022 | 920468 | 921166 | 922936 | 923553 | 924451 |

| 937407Q | 928952Q | 936705Q | FTCE2A10Q | 925788 | 925811 | 925828 | 925946 | 926476 | 926696Q |

| 9922-05-BQ | DFO-512PLF2 | 941043Q | 370-Z-223A | 927663 | 927669 | 927861Q | 928085 | 928152Q | FC1090Q002BS |

| 925774 | G1448Q | FTCE2B10Q | 937818 | FC1090Q020BS | FC1091Q005BS | FC1090Q010BS | FC1905Q002BS | F13938702190S | FC1905Q005BS |

| HF22H10VQ | FP718-5 | 933837Q | 937853Q | FC1301Q002BS | FC7005Q002BK | FTAE1A05Q | FC1240Q010XS | FTAE1A10Q | G02001 |

| 931886 | 936974Q | 941927Q | 928952Q | 909807 | 925818 | G01066 | G00980 | G00966 | G00389 |

| G04260 | G1448Q | R937852Q | R937878Q | 925023 | G00590 | G00799 | H00834003 | HF4L10VQ | HF4L25VQ |

| 937399Q | 937857Q | FBO60337 | 939930Q | 927169Q | H00834007 | PR2766 | PR875 | PR3151 | PR3435 |

| SS1C4A1AP | SS1C4B1AP | SS1D8A1AP | SS1D8B1AP | TXW1010B | TXW3E3B | TXW3E10B | TXW8A6B | TXW8C6B | PR2745 |

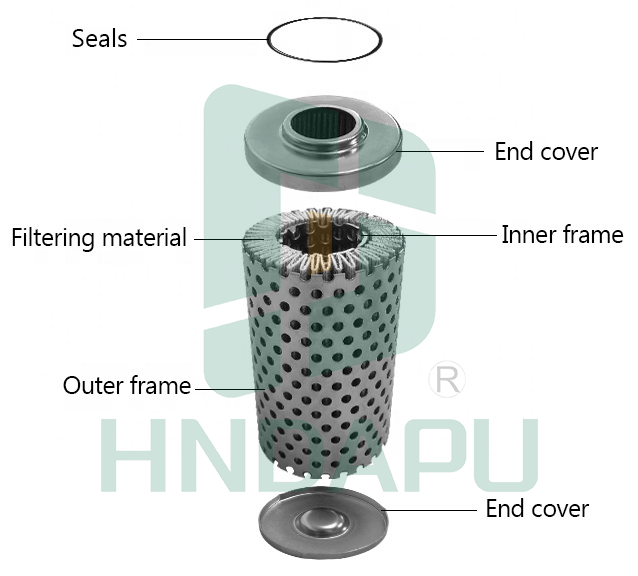

An hydraulic oil filter element is typically consists of end covers, sealing rings, inner skeleton, outer skeleton, and filter media.

►End Cover--Be used to seal both ends of the filter media and the filter element channels, to prevent the secondary pollution caused by gas or liquid leakage, and to

support the filter media to ensure the normal operation of the oil filter element.

►Sealing Ring--Located at the connection between the filter element and the machine, to prevent the filter element from loosening or oil leakage, ensuring the oil

circulation in the hydraulic system normally.

►Inner Skeleton--Serves as a support frame, with high thickness. It is typically custom-made according to working pressure to reduce the resistance caused by uneven

distribution of the filter media, withstand pressure differentials, and ensure the verticality of the filter media.

►Outer Skeleton--Serves as a protective frame, with a lower thickness and larger pore size. It is used to prevent the filter element deformation caused by external

pressure and impacts, and to provide an additional support for the filter element.

►Filter Media--The core component of a filter cartridge, used to filter impurities, separate substances, and adsorb pollutants. Various materials and specifications are

available according to different filter medium and the operating environment.

Henan Top Environmental Equipment as a industrial filter supplier, has extensive experience in customized filter cartridges. We have professional technical team to design

the most suitable filters depend on your using condition. Here are some filter parts that we can custom.

Henan Top Environmental Protection Equipment is focused on the long-term development and manufacturing of high-quality filter cartridges and filter housings, providing both standard products and custom filtration solutions for a wide range of industrial applications. Backed by advanced production equipment, experienced engineers, and a mature production management system, we are able to evaluate different working conditions and select suitable filter media, structures, and filtration ratings to meet specific performance requirements. Customization options include special dimensions, micron ratings, colors, packaging, labeling, logos, and private branding, allowing customers to receive filtration products that match both technical and market needs.

With strong R&D capability and flexible manufacturing capacity, we can support rapid new product development and small-batch trial production, often completing initial samples and production within a short lead time. Our factory operates under ISO and CE-certified quality systems and holds multiple R&D patents related to industrial filtration technology, reflecting our continuous investment in innovation and process improvement. With more than 15 years of experience in international trade, our industrial filters are exported to over 100 countries and regions, including North America, Eastern Europe, the Middle East, and Southeast Asia. Through consistent product quality, transparent communication, and reliable after-sales support, we have established long-term partnerships with distributors, OEMs, and end users worldwide. Guided by the principles of professionalism, responsibility, and integrity, we are committed to becoming a dependable filter manufacturer and filtration solution partner for customers seeking stable performance, competitive value, and long-term cooperation.

.jpg)

.jpg)

.png)

.jpg)

.png)

.png)

.png)

.png)

.png)